Have you noticed a crack on your car’s radiator? If you have, you might have considered using JB weld to fix it. The question is, just how long will JB weld last on the radiator? The short answer to this is six months to a year.

How long the weld lasts depends on the quality of the application and how often the radiator is used. If you drive on a day-to-day basis, the weld might not hold for too long due to prolonged exposure to extreme heat.

Similarly, the JB weld should be applied correctly. Otherwise, it can come off in as little as two weeks. More on this below:

How Well Does J-B Weld Hold Up to Heat?

Before we dive into its traits, it helps to know what JB weld is. Well, this is a duo-part adhesive made of epoxy. It’s used to bind an array of materials ranging from fiberglass to brick, concrete, porcelain, wood, and metal.

If you’re thinking of using it on your radiator, you might be concerned with its capability to withstand heat. Fortunately, most JB weld products are designed to withstand temperatures ranging between 250°F (121°C) and 550°F (288°C).

The RadiatorWeld Repair Kit, which is the JB weld designed for radiator repairs, holds up to temperatures of 250°F.

However, the company also makes ExtremeHeat JB welds for high-temperature applications. This particular one can withstand a temperature of up to 1,000°F (538°C).

How Long Does It Take J-B Weld to Cure on a Radiator?

The JB Weld needs a minimum of 2 to 4 hours to set. However, you’ll want to allow at least 15 to 24 hours for the adhesive to cure properly on your radiator.

This simply means that you should wait for at least a day or overnight before you can drive your car again.

But what if you’re stranded on the road with a cracked element that’s causing the radiator leak? For such occasions, I’d recommend the KwikWeld product.

It’s also manufactured by JB Weld but it takes a much shorter time to cure. This one takes just 6 minutes to set and cures fully in 4 to 6 hours. This means you can get back on the road after just a few hours.

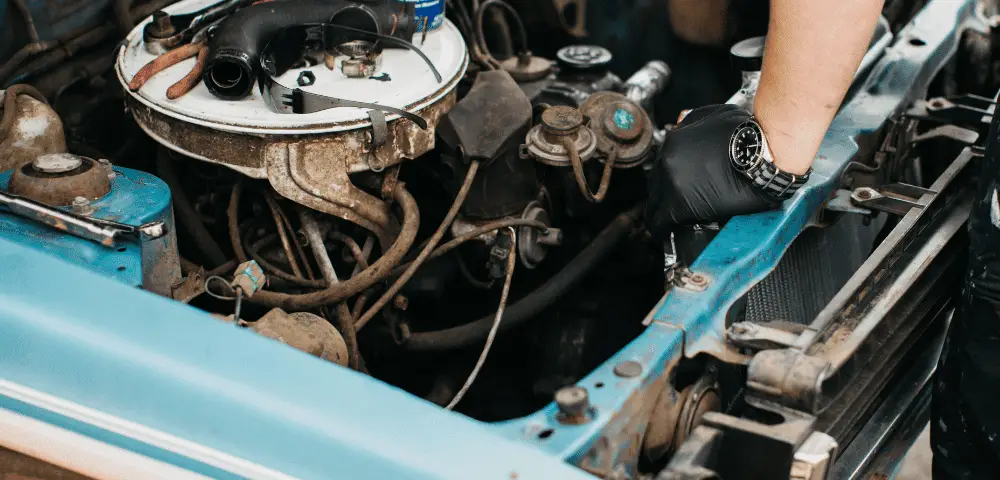

Repairing Radiator Leak or Crack with JB Weld

A small hole or crack in your aluminum radiator can be fixed fairly easily using a JB weld. But to ensure you get the best outcome, follow these steps:

Step 1: Identify the Crack

The first step in this repair process is to find the location of the crack. The easiest way to do this is to let the engine run till it reaches optimal temperature.

The idea is to allow enough pressure to accumulate so that it forces the coolant through the hole or crack in the radiator (if any). Once you identify the crack, shut off your engine, mark the area and give the engine time to cool.

Once it’s cooled, it’s time to check the marked area.

Figure out whether the crack is located below or above the current level of the coolant. If the crack is below, drain as much coolant as you need to get the coolant’s level below the hole.

Look for a drain tank cylinder that can drain the radiator tank. And while you’re at it, ensure you have enough coolant to refill the radiator once it’s fixed.

Step 2:Surface Preparation

Surface preparation is one of the most crucial steps when using a JB weld to fix a radiator crack. It determines how well the adhesive sets and cures. This, in turn, affects the strength of the resulting bond, which is important to prevent further leaking.

So what does surface preparation entail? This means getting rid of any debris, grease, and rust from the affected area.

Based on my experience from a few years ago, I find that brake cleaner does the best job of removing dirt and grime. I’d also recommend getting the adjacent area sanded down to facilitate a better bonding action with the adhesive.

Step 3: Fixing the Crack

As mentioned earlier, this epoxy comes in two parts. Each of these compounds comes in its individual tube.

The two need to be mixed in equal proportions before being applied to the damaged area. And since this J B weld sets quite fast, you should have everything ready to go before you embark on this step.

Pour the two substances on a plastic surface and mix using a wooden tool.

Next, apply the mixture to the crack. Apply liberally, ensuring that you cover the entire cracked region. All that’s left to do now is to give it time to set and hope for the best results.

Step 4: Examine the Repair

If you followed this welding process to the letter, then you have nothing to worry about.

But to err on the side of safety, it’s good to inspect everything before you hit the road. Start by putting back all the parts you removed to access the coolant system. Next, check the fluid levels, refilling any that need a top-up. Next, inspect the JB weld to confirm that it’s secure.

Once you’re sure that everything is in place, start the car and allow the engine to run for a couple of minutes. After the pressure builds up, check the fixed area to ensure that it’s no longer leaking.

If the coolant has stopped leaking, you can close the hood and drive your car without any worry.

How Long Does J-B Weld Hold Up?

The JB weld lasts anywhere between a few weeks to several years. Its lifespan depends on the specific application and the conditions it’s exposed to. Here are a couple of examples to illustrate this:

- Exposure to normal wear and tear – If it’s used to create a bond under normal conditions (no extreme temperatures), then it should last for at least 2 to 3 years.

- Extreme conditions – if the jb weld is used to bind materials exposed to extreme conditions (like high heat), it will only last for 6 months to a year. The radiator is a good example of this.

- Marine environment – if you’ll be using the welded object in a marine environment, the longest it can hold up to is a year.

Keep in mind that its longevity also depends on proper application. Whether you’re using it to seal a hole in a plastic tank or aluminum radiator, you need to allow enough time for setting and curing.

If the JB weld doesn’t set or cure properly, it can come loose in as little as 1 or 2 weeks.

On the same note, be sure to use the correct ratio of resin and hardener. They should be mixed in equal proportions. If the balance is off, the adhesive might not be set at all.

Can J-B Weld Stop Leaks?

Yes, it can. As stated on the manufacturer’s website, JB Weld does a superb job of sealing leaks. Whether the leakage is in your fuel tank, radiator, or home’s plumbing system, you can rely on this product to stop further leakage.

Conclusion

If you’ve been wondering how long the JB weld will last on the radiator, the answer is 6 months to a year.

With the radiator constantly exposed to extreme heat from the engine system, the JB weld might not last too long.

So if you’re using it to seal a crack in the radiator, consider this as a temporary fix. This means you should look for a more permanent solution or replace the radiator altogether, especially if you’re dealing with a big crack.